We are a manufacturer of oil machinery, integrated with industry and trade. Our main products are complete sets of oil press equipment, complete sets of refining equipment, palm oil processing equipment, and oil extraction equipment. The oils that can be produced include soybean oil, peanut oil, and rapeseed oil. , Cottonseed oil, sunflower oil, walnut oil, corn oil, rice bran oil, palm oil, sesame oil, olive oil and so on dozens of oils. Almost covering the global oil crops, we provide a complete set of delivery from design to manufacturing to installation and commissioning For key engineering, choosing Vicotr Company means choosing to rest assured, we will serve you wholeheartedly

-

Oil processing products-Mayonnaise

Mayonnaise is a type of O/M (oil-in-water) emulsified food. Since water is the external phase (continuous phase), it tastes very smooth and delicious. Mayonnaise contains more than 65% oil, and the emulsifier is egg yolk. The seasoning oil contains more t

Feb 05, 2021 -

Oil processing products-Cocoa Butter Substitute

The preparation process of cocoa butter substitutes mainly consists of three parts: hydrogenation, transesterification and fractionation.

Feb 04, 2021 -

Oil processing products-Shortening

Shortening is derived from the word "short" in English, which means that using this oil to process biscuits, etc., can make the product very crisp, so the oil with this property is called "shortening"

Feb 03, 2021 -

Oil processing products-Margarine

The production process of margarine includes five stages: blending of raw materials and auxiliary materials, emulsification, quenching, kneading, packaging and maturation.

Feb 02, 2021 -

Oil processing products-Blending oil

Blending oil is a new type of edible oil product that is formulated with two or more edible fats and oils in an appropriate proportion according to certain needs.

Feb 01, 2021 -

Oil processing products-Hydrogenated oil

Hydrogenation process:Raw oil → pretreatment (refining) → deoxygenation, dehydration → (catalyst →) hydrogenation → (hydrogen →) filtering → re-bleaching → deodorization → hydrogenated oil.

Jan 31, 2021 -

Oil refining-De-fat

Oil is a mixture of various fatty acid triglycerides (triglycerides for short). Different fatty acids have different melting points of fats. Triglycerides with high saturation have a high melting point; triglycerides with low saturation have a lower melti

Jan 30, 2021 -

Oil refining-Dewaxing

The process of removing wax in oil is called "dewaxing". There are currently three methods for dewaxing rice bran oil in my country: filter press filteration, bag hanging filteration and centrifugal separation.

Jan 29, 2021 -

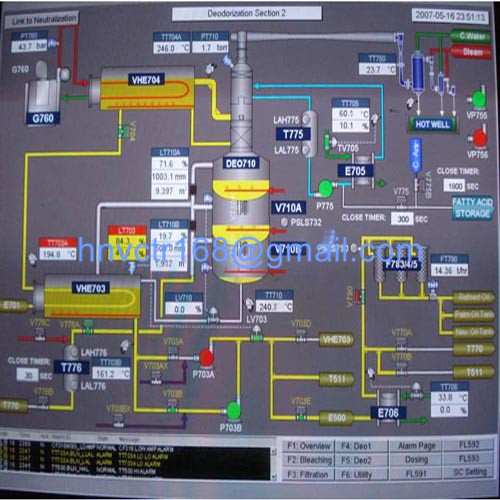

Oil refining-Deodorizing(Part 3)

The deodorizing process can be divided into three types: batch type, continuous type and semi-continuous type. The batch deodorizing process should be adopted for the processing capacity less than 20 tons/day; the continuous deodorizing process can be use

Jan 28, 2021 -

Oil refining-Deodorizing(Part 2)

1. Precautions for equipment selection;2. Equipment layout;3. Quality of deodorized oil

Jan 27, 2021 -

Oil refining-Deodorizing(Part 1)

There are many methods for deodorizing, including vacuum steam deodorizing, gas blowing, hydrogenation and polymerization. At present, the vacuum steam deodorizing method is the most widely used and the best effect at home and abroad.

Jan 26, 2021 -

Oil refining-Bleaching

The bleaching method of oil include sunlight bleaching method (also known as oxidation method), chemical bleaching method, heating method and adsorption method. At present, the most widely used method is the adsorption method,

Jan 25, 2021 -

Oil refining-Desolventizing

The operation of removing the residual solvent in the extracted oil is called "desolventizing". The residual amount of solvent in the oil after desolventizing should not exceed 50 mg/L.At present, the most widely used method at home and abroad is the

Jan 24, 2021 -

Oil refining-Physical refining

The physical refining of fats and oils is distillation and de-acidification, which is based on the significant difference in volatility between triglycerides and free fatty acids (under vacuum conditions).

Jan 23, 2021 -

Oil refining-Zenith neutralization method

The zenith neutralization method consists of three stages. The first stage is crude oil degumming, the second stage is deacidification, and the third stage is bleaching.

Jan 22, 2021 -

Oil refining-Alkali refining and de-acidification process parameters

Alkali refining and de-acidification process parameters:①Quality requirements of degummed oil.②In terms of processing capacity.③The concentration and amount of lye in the alkali refining must be selected correctly.④ The batch caustic refinin

Jan 21, 2021