Oil refining-Deodorizing(Part 2)

1. Precautions for equipment selection

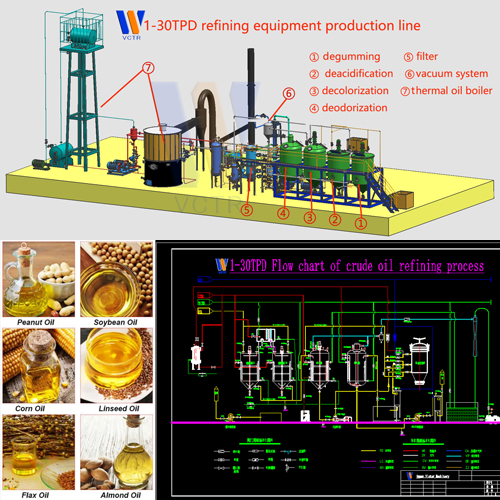

①The deodorizing equipment has various forms such as single-shell tower, double-shell tower, tank type, and horizontal type. The design can be selected according to specific conditions.

②The vacuum device can use three-stage or four-stage steam jet pump, and the selected power steam pressure should be adapted to the pressure of the equipped boiler; but it is not suitable to use a pressure lower than 0.6 MPa to save steam consumption.

③Deodorized oil should be passed through a safety filter to further remove trace impurities in the oil.

④The Oil to oil heat exchanger for recovering heat energy has tube and spiral plate type, and the spiral plate heat exchanger should be used first in the design.

⑤The fatty acid capturer should be directly spraying condenser.

⑥The deodorized oil extraction pump should be a centrifugal pump with good sealing performance and high temperature resistance. High temperature canned motor pumps are preferred.

⑦The conduction oil heating system should be equipped with thermometers, pressure gauges, check valves, filters, alarms and other instruments to supervise, measure, indicate, and alarm the operation to ensure safe production. In order to prevent accidents caused by sudden power failure, the conduction oil heating system should be equipped with a hand pump so that the conduction oil can continue to circulate and cool down after the power failure.

2. Equipment layout

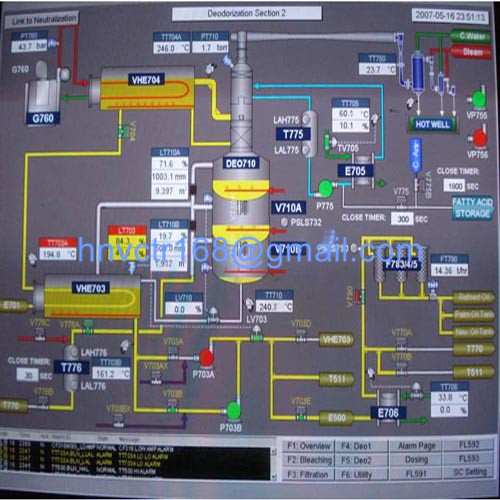

①The heat conduction furnace room should be set up separately or separated by walls in the workshop. The arrangement should be as close as possible to the deodorizing tower to reduce heat waste.

②The water outlet of the steam jet pump and condenser should be 11 meters above the liquid level of the water seal tank.

③The deaerator should be placed on the second floor, and the position of the deodorizating tower should be appropriately higher to facilitate the sucking of the oil by the sucking pump.

3. Quality of deodorized oil

①Quality standard of deodorized oil:

According to the national standards and national professional standards of the corresponding oil products.

②The quality of citric acid:

Properties: white powder or granules;

Grade: Food grade;

Purity: ≥99%.

③Quality of heat transfer oil.

The heat transfer oil should be a variety that is non-toxic, odorless, good in thermal stability, strong in oxidation resistance, and non-corrosive to the equipment. Its main composition is long-carbon linear saturated hydrocarbon.

Hot tags:Deodorizing,Deodorizing equipment,Deodorizing Equipment layout,,Quality of deodorized oil,

①The deodorizing equipment has various forms such as single-shell tower, double-shell tower, tank type, and horizontal type. The design can be selected according to specific conditions.

②The vacuum device can use three-stage or four-stage steam jet pump, and the selected power steam pressure should be adapted to the pressure of the equipped boiler; but it is not suitable to use a pressure lower than 0.6 MPa to save steam consumption.

③Deodorized oil should be passed through a safety filter to further remove trace impurities in the oil.

④The Oil to oil heat exchanger for recovering heat energy has tube and spiral plate type, and the spiral plate heat exchanger should be used first in the design.

⑤The fatty acid capturer should be directly spraying condenser.

⑥The deodorized oil extraction pump should be a centrifugal pump with good sealing performance and high temperature resistance. High temperature canned motor pumps are preferred.

⑦The conduction oil heating system should be equipped with thermometers, pressure gauges, check valves, filters, alarms and other instruments to supervise, measure, indicate, and alarm the operation to ensure safe production. In order to prevent accidents caused by sudden power failure, the conduction oil heating system should be equipped with a hand pump so that the conduction oil can continue to circulate and cool down after the power failure.

2. Equipment layout

①The heat conduction furnace room should be set up separately or separated by walls in the workshop. The arrangement should be as close as possible to the deodorizing tower to reduce heat waste.

②The water outlet of the steam jet pump and condenser should be 11 meters above the liquid level of the water seal tank.

③The deaerator should be placed on the second floor, and the position of the deodorizating tower should be appropriately higher to facilitate the sucking of the oil by the sucking pump.

3. Quality of deodorized oil

①Quality standard of deodorized oil:

According to the national standards and national professional standards of the corresponding oil products.

②The quality of citric acid:

Properties: white powder or granules;

Grade: Food grade;

Purity: ≥99%.

③Quality of heat transfer oil.

The heat transfer oil should be a variety that is non-toxic, odorless, good in thermal stability, strong in oxidation resistance, and non-corrosive to the equipment. Its main composition is long-carbon linear saturated hydrocarbon.

Hot tags:Deodorizing,Deodorizing equipment,Deodorizing Equipment layout,,Quality of deodorized oil,