Oil refining-Deodorizing(Part 1)

1. Purpose of deodorizing

Pure fatty acid triglycerides are colorless and odorless, but natural oils and fats have their own special odor. Odor is an oxidation product, which is further oxidized to generate peroxy compounds, which decompose into aldehydes, thus making the oil taste. In addition, odors such as solvent, soap and earthy odors are also produced during the oil production process. The process of removing the peculiar smell (flavoring substances) of fats and oils is called "deodorizing" of fats and oils.

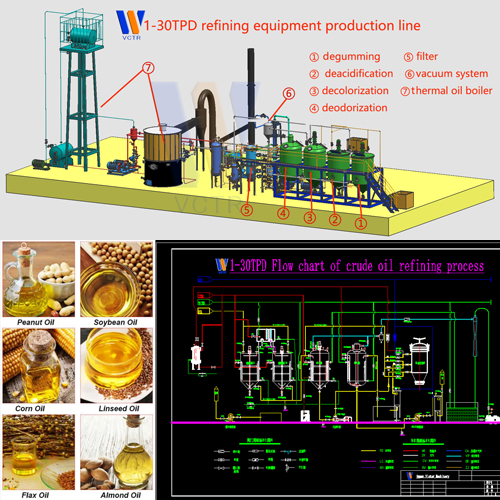

The deodorizing of the extracted oil (called "desolventizing" when the process parameters fail to meet the deodorizing requirements) is very important. Before deodorizing, hydration, alkali refining and bleaching must be carried out to create good deodorizing conditions, which is beneficial to the removal of residual solvents and other odors in the oil.

2. Deodorizing method

There are many methods for deodorizing, including vacuum steam deodorizing, gas blowing, hydrogenation and polymerization. At present, the vacuum steam deodorizing method is the most widely used and the best effect at home and abroad.

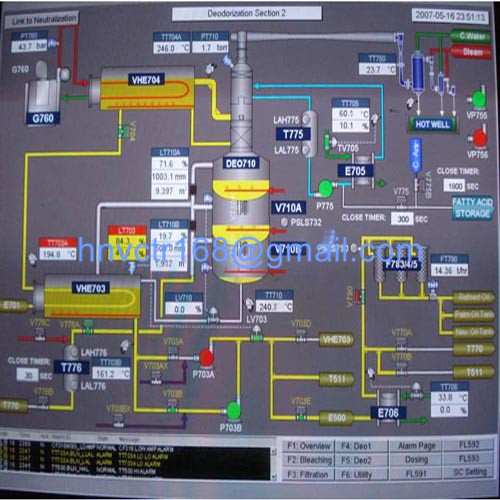

Vacuum steam deodorizing is a process in which superheated steam (under vacuum) is used in the deodorizing pot to remove odorous substances in the oil. The principle of vacuum steam deodorizing is that water vapor passes through oils containing odorous components, vapor-liquid contact, the water vapor is saturated with the odorous components that volatilize, and is selected and removed according to the partial pressure ratio.

3. Deodorizing process parameters

①Batch deodorizing oil temperature is 160~180℃, residual pressure is 800 Pa, time is 4~6 hours, direct steam injection is 10%~15% of oil weight.

②The continuous deodorizing oil temperature is 240~260℃, the time is 60~120 minutes, the residual pressure is below 800 Pa, and the direct steam injection is 2%~4% of the oil weight.

③The amount of citric acid added should be less than 0.02% of the oil weight. ④The temperature of conduction oil should be controlled within the range of 270~290℃.

Pure fatty acid triglycerides are colorless and odorless, but natural oils and fats have their own special odor. Odor is an oxidation product, which is further oxidized to generate peroxy compounds, which decompose into aldehydes, thus making the oil taste. In addition, odors such as solvent, soap and earthy odors are also produced during the oil production process. The process of removing the peculiar smell (flavoring substances) of fats and oils is called "deodorizing" of fats and oils.

The deodorizing of the extracted oil (called "desolventizing" when the process parameters fail to meet the deodorizing requirements) is very important. Before deodorizing, hydration, alkali refining and bleaching must be carried out to create good deodorizing conditions, which is beneficial to the removal of residual solvents and other odors in the oil.

2. Deodorizing method

There are many methods for deodorizing, including vacuum steam deodorizing, gas blowing, hydrogenation and polymerization. At present, the vacuum steam deodorizing method is the most widely used and the best effect at home and abroad.

Vacuum steam deodorizing is a process in which superheated steam (under vacuum) is used in the deodorizing pot to remove odorous substances in the oil. The principle of vacuum steam deodorizing is that water vapor passes through oils containing odorous components, vapor-liquid contact, the water vapor is saturated with the odorous components that volatilize, and is selected and removed according to the partial pressure ratio.

3. Deodorizing process parameters

①Batch deodorizing oil temperature is 160~180℃, residual pressure is 800 Pa, time is 4~6 hours, direct steam injection is 10%~15% of oil weight.

②The continuous deodorizing oil temperature is 240~260℃, the time is 60~120 minutes, the residual pressure is below 800 Pa, and the direct steam injection is 2%~4% of the oil weight.

③The amount of citric acid added should be less than 0.02% of the oil weight. ④The temperature of conduction oil should be controlled within the range of 270~290℃.