The effect of refining process on trans fatty acids

Trans fatty acid (TFA) is a general term for unsaturated fatty acids containing at least one trans-configuration double bond, including monounsaturated trans fatty acids and polyunsaturated trans fatty acids. Excessive intake of trans fatty acids can easily cause coronary heart disease, increase blood viscosity and cohesion, form thrombus, reduce memory, and affect development. my country’s GB 28050—2011 "General Principles for Nutrition Labeling of Prepackaged Foods in National Food Safety Standards" clearly stipulates the content of mandatory labeling: When food ingredients contain or use hydrogenated and/or partially hydrogenated fats and oils in the production process, the nutritional composition should also be included in the nutritional composition table. Indicate the content of trans fat (acid). The standard stipulates that when the content of trans fatty acids in food is less than or equal to 0.3 g/100 g, it can be marked as "0" or "no" or "free" trans fatty acids; at the same time, the standard also states that daily intake of trans fatty acids should not be Excessive intake of more than 2.2 g is harmful to health. Therefore, in order to control the content of trans fatty acids, it is very important to study the content of trans fatty acids in the refining process of vegetable oils. This paper studies the effect of refining process on trans fatty acids in corn oil. While meeting the quality index of corn oil and meeting the requirements of national standards, it optimizes the process parameters of the refining process, reduces the content of trans fatty acids in corn oil, and hopes to produce edible vegetable oil. for reference.

1. Experimental method

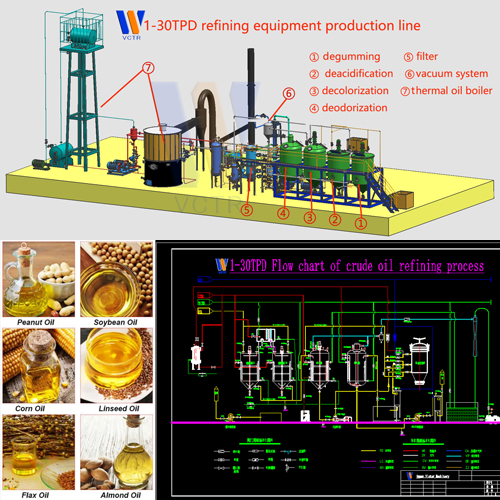

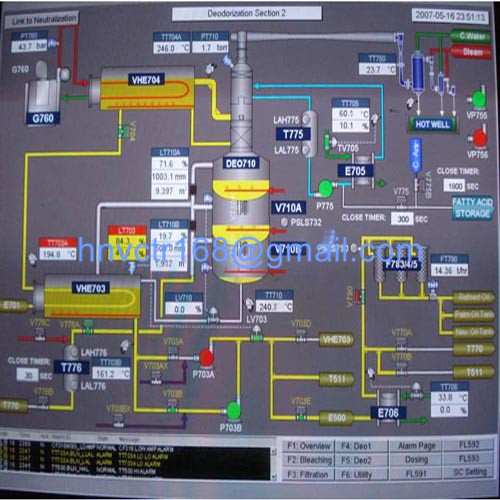

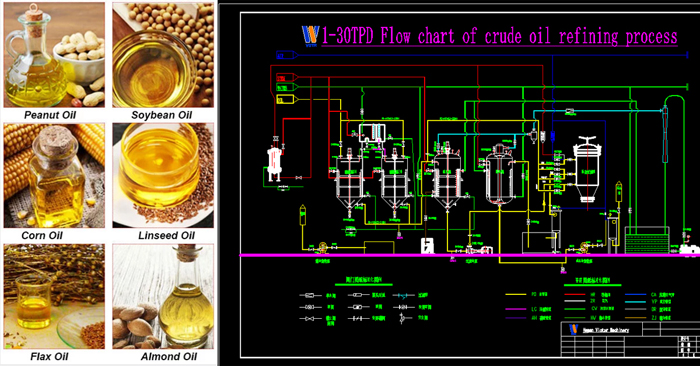

Using corn crude oil as raw material, it is acidified and degummed (addition of phosphoric acid is 1%, degumming temperature is 60 ℃, degumming time is 20 min), alkali refining and deacidification (the amount of alkali added is 1.2 times the theoretical value, and the mass fraction of NaOH is 8.71%. Acid temperature 60 ℃, deacidification time 20 min), water eluting soap (washing temperature 85 ℃, stirring time 15 min), adsorption decolorization (decolorization temperature 105 ℃, addition of clay 1.5%, decolorization time 30 min), and then proceed Deodorization treatment. Deodorization treatment: Put 500 mL of decolorized corn oil into a deodorization bottle, deodorize for a period of time at a vacuum degree of 200-300 Pa and a certain deodorization temperature. After deodorization, cool down and collect.

2: Research on the refining process

2.1 The content of trans fatty acids in corn oil in each refining process The content of trans fatty acids in corn crude oil, neutralized oil, decolorized oil, and deodorized oil (deodorization temperature 230 ℃, deodorization time 60 min) were determined respectively

There are no trans fatty acids in corn crude oil, neutralized oil, and decolorized oil. The content of trans fatty acids in deodorized oil is 0.15%, indicating that trans fatty acids are mainly produced in the deodorizing section. The deodorization section uses steam stripping under high temperature and vacuum conditions to remove undesirable flavors, heat-sensitive pigments, free fatty acids and other small molecular substances in the oil. While removing these substances, trans fatty acids are produced.

2.2 The effect of deodorization temperature on the content of trans fatty acids in corn oil

Select the deodorization temperature of 210, 230, 250, 270 ℃ respectively to carry out the deodorization experiment for 60 minutes to detect the content of trans fatty acid in the deodorized oil, and investigate the effect of deodorization temperature on the content of trans fatty acid in corn oil

2.3 The effect of deodorization temperature and deodorization time on the content of trans fatty acids in corn oil Select the deodorization temperature of 210, 230, 250, 270 ℃ and the deodorization time of 60, 80, 100, 120 min, respectively, to detect the content of trans fatty acids in the deodorized oil. To investigate the effect of deodorization temperature and deodorization time on the content of trans fatty acids in corn oil. With the increase of deodorization temperature and deodorization time, the content of trans fatty acids in corn oil showed an increasing trend. The deodorization temperature is between 210 and 250 ℃, the trans fatty acid content rises slowly, and the deodorization temperature is higher than 250 ℃, the trans fatty acid content begins to increase rapidly; the deodorization time exceeds 100 min, the trans fatty acid content increases rapidly. The deodorization temperature and deodorization time in the refining process of vegetable oil have significant effects on the content of trans fatty acids.

3 Conclusion

Trans fatty acids in corn oil are mainly produced in the deodorization section of refining. With the increase of deodorization temperature and the extension of deodorization time, the content of trans fatty acids shows an increasing trend. The deodorization temperature is within 230 ℃, the deodorization time is within 100 minutes, the trans fatty acid content in deodorized corn oil is less than 0.3%, which meets the requirements of GB 28050-2011 that the trans fatty acid content is less than or equal to 0.3 g/100 g, which can be marked as " It does not contain "trans fatty acids", and the oil quality index also meets the national standard first-class corn oil requirements.