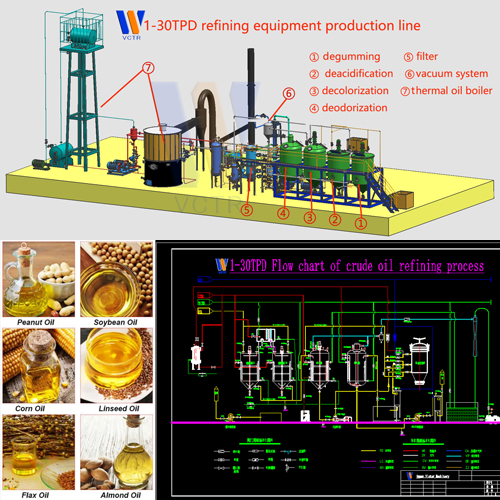

100TPD Palm Oil Dry Process Refining & Fractionation plant

Palm Oil Dry Process Refining & Fractionation plant

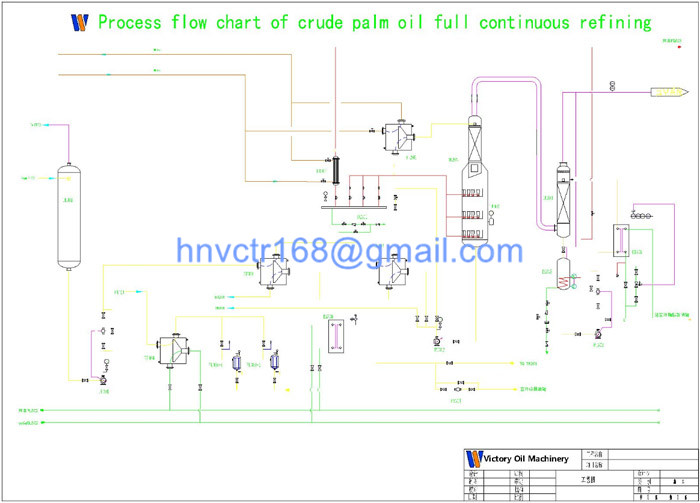

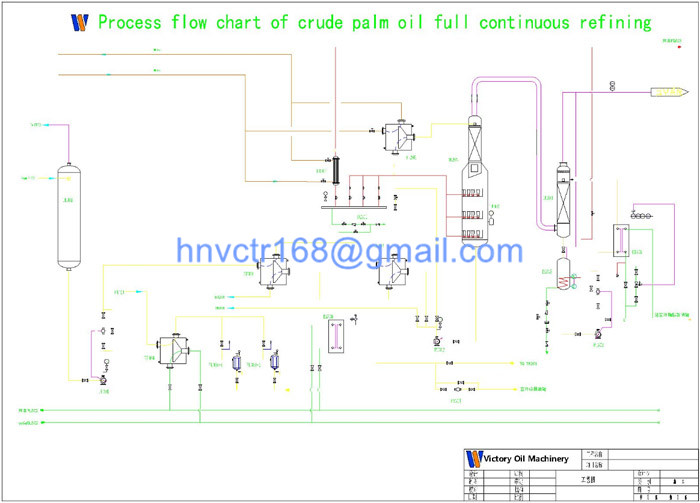

1.Refining Process Description

1) Dry Degumming

Crude palm oil contains phospholipids and other gums, and uses a continuous dry degumming process, Phosphoric acid is uniformly mixed with crude oil through a quantitative pump, and the gum is adsorbed and mixed through the acid reaction tank, and then goes to the subsequent decolorization section to separate the gum during the decolorization process.

2) Continuous bleaching and filtering section

The newly completed continuous bleaching section uses two alternate filters. The mixing oil and earth flow into the Vacuum bleaching tower. The bleached oil is pumped through the alternate filters. The valves are automatic switched. Filtered oil is pumped into deodorization section after safety filters.

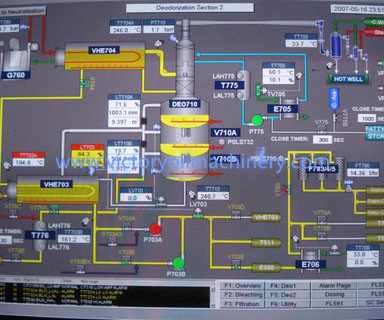

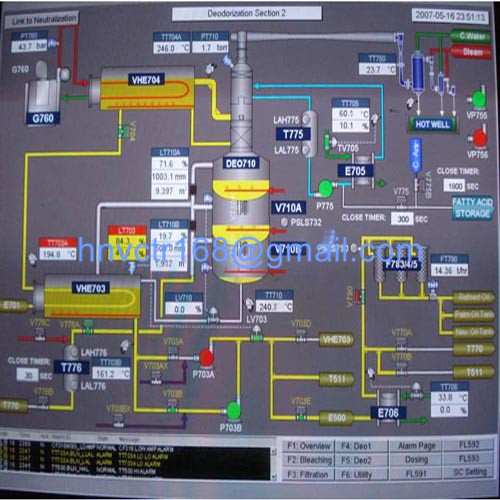

3) Deodorization section

After heating with deodorized oil, the un-deodorized oil is pumped into vacuum heat exchanger to be heated with conduction oil boiler before deodorization system.Before deodorizer, the heated oil needs to pass through sieve-plate columns special designed to remove large amount of fatty acid. Right here, the fatty acid amount to absolutely low. Some odor material needs a longer time to be removed, but will be finally removed or inactive in column-plates. The oil reserved in the column-plates has been sprayed a ratio of mixing steam.The mixture of fatty acid and steam from deodorizer is collected into the capture-purification unit, and be cooled by circulating acid-oil as passing through the first layer packing.Acid-oil and other volatile material are condensed right here and collected into the recovery tank. The liquid level of acid-oil tank is remained through controlling the amount of cooling recovery acid-oil discharged. Deodorized oil needs deep de-acidification and deodorization by pumping into the packing tower, and then to be discharged to have heat exchanging with pre-deodorizing oil, lastly to be cooled.After passing through alternate polish filter, the deodorized oil is cooled to storage temperature with cooling water. Addition of antioxidant depends on the quality requirement.

4) Quality of crude palm oil

1.Refining Process Description

1) Dry Degumming

Crude palm oil contains phospholipids and other gums, and uses a continuous dry degumming process, Phosphoric acid is uniformly mixed with crude oil through a quantitative pump, and the gum is adsorbed and mixed through the acid reaction tank, and then goes to the subsequent decolorization section to separate the gum during the decolorization process.

2) Continuous bleaching and filtering section

The newly completed continuous bleaching section uses two alternate filters. The mixing oil and earth flow into the Vacuum bleaching tower. The bleached oil is pumped through the alternate filters. The valves are automatic switched. Filtered oil is pumped into deodorization section after safety filters.

3) Deodorization section

After heating with deodorized oil, the un-deodorized oil is pumped into vacuum heat exchanger to be heated with conduction oil boiler before deodorization system.Before deodorizer, the heated oil needs to pass through sieve-plate columns special designed to remove large amount of fatty acid. Right here, the fatty acid amount to absolutely low. Some odor material needs a longer time to be removed, but will be finally removed or inactive in column-plates. The oil reserved in the column-plates has been sprayed a ratio of mixing steam.The mixture of fatty acid and steam from deodorizer is collected into the capture-purification unit, and be cooled by circulating acid-oil as passing through the first layer packing.Acid-oil and other volatile material are condensed right here and collected into the recovery tank. The liquid level of acid-oil tank is remained through controlling the amount of cooling recovery acid-oil discharged. Deodorized oil needs deep de-acidification and deodorization by pumping into the packing tower, and then to be discharged to have heat exchanging with pre-deodorizing oil, lastly to be cooled.After passing through alternate polish filter, the deodorized oil is cooled to storage temperature with cooling water. Addition of antioxidant depends on the quality requirement.

4) Quality of crude palm oil

| Acid value(mg KOH/g) | ≤10 |

| FFA content | ≤5% |

| Water content(%) | ≤0.5 |

| Insoluble impurity(%) | ≤0.1 |

| DOBI | ≥2.4min |

| Phosphorus content | ≤20ppm |

5) Quality of final product

| RBD Palm oil RBD | |

| Color (Lovibond colorimetry5 /4”) | Y25,R2.5 |

| Flavor and color | Natural |

| Insoluble impurity(%) | ≤ 0.05 |

| Moisture and volatility(%) | ≤ 0.05 |

| Acid value(mg KOH/g) | ≤ 0.2 |

| Peroxide value(m mol/kg) | ≤ 0.5 |

6) Consumption

| Degumming and decolorizing section | |

| Steam(3Bar)(Kg/t) | ≦15 |

| Electricity(Kwh/t) | 2.5 |

| Bleaching earth(Kg/t) | 5-30 |

| Refining loss | ≦24%*waste clay (dry basis) 24%*) |

| Deodorization section | |

| Steam for vacuum(8Bar)(Kg/t) | ≦42 |

| Steam for stripping(3Bar)(Kg/t) | ≦6 |

| Electricity(Kwh/t) | ≦19 |

| Diesel oil (Kg/t) | ≦3.5 |

| Refining loss (%) |

≤(0.2+0.15×input oil FFA)% |