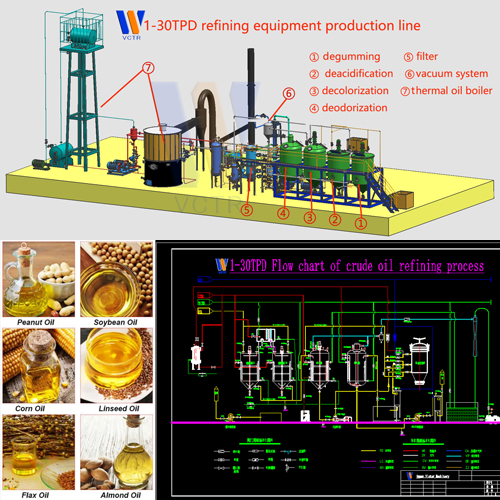

Palm Oil Full Continuous Fractionation Engineering Equipment

- Henan Victor Machinery Equipment Co.,Ltd

- Made In China

- Palm oil Production Machine-80

The refining fraction of palm oil designed and manufactured by our company has its own unique technology and patents, simple operation, high degree of automation, high oil yield, and all indicators of finished palm oil reach the standard

Palm Oil Full Continuous Fractionation Engineering Equipment details

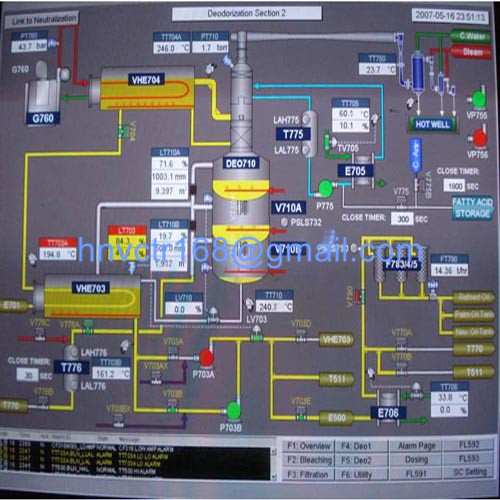

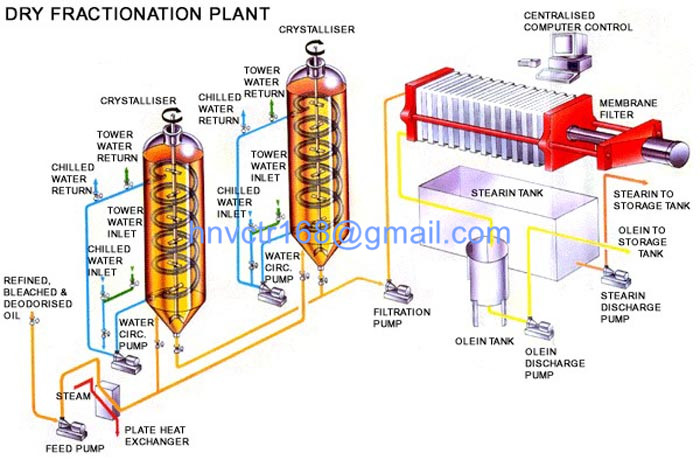

Palm Oil Fractionation Process Description

The dry fractionation of palm oil includes crystallization section and filtration section. The plant is designed to continuously process RBD Palm Oil with operations as described in the following sections:

1. Crystallization Section

Feedstock is heated and pumped to crystallizers. The oil is cooled according to a pre-determined cooling profile by means of controlling the temperature of the cooling medium circulating in the cooling coils. The design of this cooling profile depends on the quality of feedstock and the quality of olein/stearin fractions required. This is to keep the oil homogenized with frequency mechanical agitation in the crystallizers. A typical cooling program lasts for a certain time, depending on the quality of feedstock and product. When the oil appears as a thick semi-solid mass (slurry) containing stearin crystals in liquid olein, it is ready for filtration. If the crystallization result is not desirable, the slurry can be circulated through the feed oil heater for re-heating before being sent back to the feed oil tank for re-processing.

2. Filtration Section

When crystallization is completed, the slurry is fed to the Membrane Filter Press for filtration. The operation includes filter feed, filtering, squeezing and cake releasing.When the chambers are full after cake forming, the pumping will stop and the membranes are inflated to squeeze dry the filter cakes. After which, the residual oil in the core is blown dry by compressed air. Thereafter, the filter is opened and the cake will drop into a stearin tank. The stearin cake is melted in this tank by steam coils before it is discharged to storage. Olein flows into the olein tank, and is pumped to the outer olein storage tank.The membrane filter press requires cleaning after several filtration cycles.

Fractionation Technical Parameters:

3. Quality of RBDPO required:

| I.V.(g I2/100g) | 50~52 |

| Moisture & impurities(%) | ≤ 0.1 |

| FFA content(%) | ≤ 0.1 |

| Inlet temperature(℃) | 50℃ |

4.Quality of final product (based on freshly processed oil sample)

| Olein | Stearin | |

| I.V.(g I2/100g) | ≥56 | 32-34 |

| Moisture & impurities(%) | 0.1 | 0.1 |

| Yield(%) | ≥79±2 | ≤21±2 |

5.Utilities consumptions :

| Steam 3bar(Kg/T) | ≤ 50(for heating the RBD palm oil and palm stearin,not include vam chiller) |

| Electricity(KWh/T) | ≤ 22(without the power for screw chiller) |

| Cooling water(m³/T) | ≤ 0.2(only for make-up water) |

| Compressed air | ≤ 10(Nm³/h) |

tag : Palm Oil Extraction Plant,Palm Oil Machine,Palm Oil Refining

Palm Oil Full Continuous Fractionation Engineering Equipment,The refining fraction of palm oil designed and manufactured by our company has its own unique technology and patents, simple operation, high degree of automation, high oil yield, and all indicators of finished palm oil reach the standard