soybean solvent extraction,sunflower seed solvent extraction ,

- Henan Victor Machinery Equipment Co.,Ltd

- Made In China

- Oil solvent extraction equipment-34

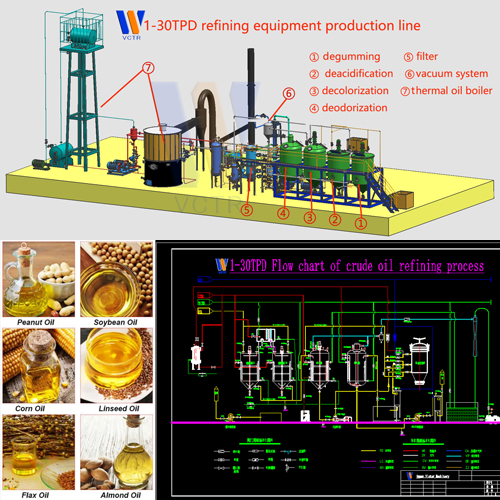

High-quality solvent extraction device, which is mainly composed of extraction desolventizer, evaporator, DTDC decontamination machine, stripper and condenser, low solvent consumption, high degree of automation, processing capacity 20-1000TPD

soybean solvent extraction,sunflower seed solvent extraction , details

1. High quality solvent extraction plant, oil cake solvent extraction equipment introduction

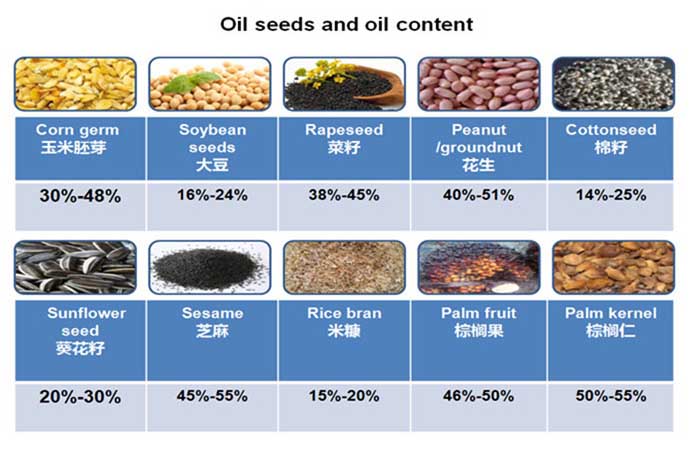

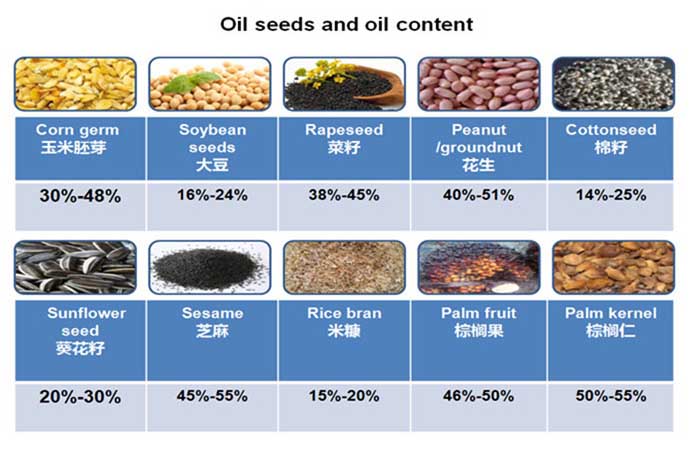

It is composed mainly of extractor desolventizer, evaporators, stripping tower and condensers. The oil can be extracted from oil-bearing materials through solvent contacting, steeping or spraying of oil flake (soybean) or pre-pressed cake (rapeseed, cottonseed, sunflower seed, peanut, rice bran, sesame, tea seed, coconut etc.) based on solvent extractor, stainless steel tube condenser, aluminum alloy tube condenser or plate condenser, exhaust gas freezing recovery device are applied in the technology with advanced process and good performance.

1. solvent extraction machine

2. suite for soybean, corn germ, peanut, sesame, rapeseed, rice bran, cottonseed, tea seed, sunflower seed oil press

3. pure oil, edible oil quality

4. various capacity: 10t/d, 20t/d, 30t/d, 40t/d, 50t/d, 60t/d, 70t/d, 80t/d,100t/d, 150t/d

5. used for hot and cold press

2. High quality small solvent extraction plant, oil cake solvent extraction equipment process

(1)The material (for pretreatment) is sent to rotary extraction by the scraper conveyor. The material will extracted by the solvent or mix oil. After this step, we will get meal and mix oil.

(2) Meal is sent to toaster. Through the toaster, the solvent in the meal will separate from the meal. The solvent goes to condenser and is recycled to rotary extraction.

(3) After the mix oil from the rotary extraction enters into 1st evaporator and 2nd evaporator, most of the solvent in the mix oil is separated.

(4) The mix oil from 2nd evaporator goes to stripping tower and almost all the solvent is separated. From the stripping tower, we can get crude oil and solvent. The solvent is sent to condenser and is recycled to rotary extraction.

3. Equipment:

(1) Solvent pumps: continuously spray solvent to the rotary-type extractor.

(2) Roary extractor: Spray and soak the pre-pressed cake with solvent so that oil fats can be dissolved in solvent(form miscella). After processing, you can get wet meal and miscella (mixed oil).

(3) DTDC: usd to separate the solvent from the wet meal.

(4) Miscella tank 1st: pump the miscella (oil with solvent) in to the miscella 1st , and then add 10% saline water to it. The phospholipid and impurities in the miscella will react with the saline wter, at last the reactant precipitate, reaching the goal of purifying.

(5) Miscella tank 2nd: the purified miscella will be pumped into it.

(6) Miscella stripping: it will remove the remaining solvent in miscella. And the solvent will be discharged to condenser for recycling.

(7) condensers: used to cooling the solvent gas separated from the wet meal and miscella for recycling.

2>. Solvent Extraction Workshop

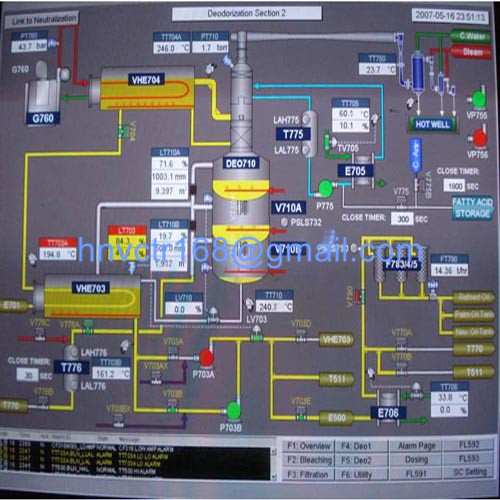

Evaporation And Steam Stripping

↑

Sunflower Seed Flakes→Oil Extraction→Mixed Oil Processing→Crude Oil

↓

Solvent Collection←Wet Cake Desolventizing→Finished Cake.

4. High quality small solvent extraction plant, oil cake solvent extraction equipment feature:

1. the solvent extract equipment adopts stainless steel fixed grid tray, frequency conversion speed regulation, extract equipment storage tank feeding level is automatic control, high extracting efficiency, low energy consumption; Extracting condenser, steam degassing condenser, stripping condenser, evaporative condenser, the final condenser are aluminum alloy tube-type condenser, the condensation effect is fast.

2. wet meal dissolution using DTC toast-desolventizing, dissolution, drying in one machine. The production of finished meal powder is small, good color, toast-desolventizing level is self automatic control.

3. adopts film evaporation process, evaporation temperature is low, crude oil quality is good, energy saving, secondary steam from toaster and waste heat can be utilized, as the first evaporator heat source.

4. Steam-lift crude oil and steam mixed oil heat exchange, save energy.

5. the tail gas recovery uses the water bath type tail gas recovery device, the tail gas recovery two times utilization, reduces the solvent consumption.

It is composed mainly of extractor desolventizer, evaporators, stripping tower and condensers. The oil can be extracted from oil-bearing materials through solvent contacting, steeping or spraying of oil flake (soybean) or pre-pressed cake (rapeseed, cottonseed, sunflower seed, peanut, rice bran, sesame, tea seed, coconut etc.) based on solvent extractor, stainless steel tube condenser, aluminum alloy tube condenser or plate condenser, exhaust gas freezing recovery device are applied in the technology with advanced process and good performance.

1. solvent extraction machine

2. suite for soybean, corn germ, peanut, sesame, rapeseed, rice bran, cottonseed, tea seed, sunflower seed oil press

3. pure oil, edible oil quality

4. various capacity: 10t/d, 20t/d, 30t/d, 40t/d, 50t/d, 60t/d, 70t/d, 80t/d,100t/d, 150t/d

5. used for hot and cold press

2. High quality small solvent extraction plant, oil cake solvent extraction equipment process

(1)The material (for pretreatment) is sent to rotary extraction by the scraper conveyor. The material will extracted by the solvent or mix oil. After this step, we will get meal and mix oil.

(2) Meal is sent to toaster. Through the toaster, the solvent in the meal will separate from the meal. The solvent goes to condenser and is recycled to rotary extraction.

(3) After the mix oil from the rotary extraction enters into 1st evaporator and 2nd evaporator, most of the solvent in the mix oil is separated.

(4) The mix oil from 2nd evaporator goes to stripping tower and almost all the solvent is separated. From the stripping tower, we can get crude oil and solvent. The solvent is sent to condenser and is recycled to rotary extraction.

3. Equipment:

(1) Solvent pumps: continuously spray solvent to the rotary-type extractor.

(2) Roary extractor: Spray and soak the pre-pressed cake with solvent so that oil fats can be dissolved in solvent(form miscella). After processing, you can get wet meal and miscella (mixed oil).

(3) DTDC: usd to separate the solvent from the wet meal.

(4) Miscella tank 1st: pump the miscella (oil with solvent) in to the miscella 1st , and then add 10% saline water to it. The phospholipid and impurities in the miscella will react with the saline wter, at last the reactant precipitate, reaching the goal of purifying.

(5) Miscella tank 2nd: the purified miscella will be pumped into it.

(6) Miscella stripping: it will remove the remaining solvent in miscella. And the solvent will be discharged to condenser for recycling.

(7) condensers: used to cooling the solvent gas separated from the wet meal and miscella for recycling.

| Main economic and technical parameters(100-500T/D) | ||

| 1 | Residual oil in meal | ≤ 1% (Soybean) |

| 2 | Solvent consumption | ≤ 1.5Kg/T (N-hexane) |

| 3 | Crude oil moisture and volatile matter | ≤ 0.30% |

| 4 | Power consumption | Installed capacity:320KW |

| 5 | Steam consumption | ≤ 280Kg/T (0.8MPa) |

| 6 | Water consumption | 0.3t/T soybean cake |

| 7 | Finished meal moisture | ≤ 10-13% (adjustable) |

| 8 | Urease activity | 0.05-0.25 |

| 9 | Residual solvent in finished meal | ≤ 100PPM (qualified detonated experiment) |

| 10 | Mechanical impurity | ≤ 0.20% |

Evaporation And Steam Stripping

↑

Sunflower Seed Flakes→Oil Extraction→Mixed Oil Processing→Crude Oil

↓

Solvent Collection←Wet Cake Desolventizing→Finished Cake.

4. High quality small solvent extraction plant, oil cake solvent extraction equipment feature:

1. the solvent extract equipment adopts stainless steel fixed grid tray, frequency conversion speed regulation, extract equipment storage tank feeding level is automatic control, high extracting efficiency, low energy consumption; Extracting condenser, steam degassing condenser, stripping condenser, evaporative condenser, the final condenser are aluminum alloy tube-type condenser, the condensation effect is fast.

2. wet meal dissolution using DTC toast-desolventizing, dissolution, drying in one machine. The production of finished meal powder is small, good color, toast-desolventizing level is self automatic control.

3. adopts film evaporation process, evaporation temperature is low, crude oil quality is good, energy saving, secondary steam from toaster and waste heat can be utilized, as the first evaporator heat source.

4. Steam-lift crude oil and steam mixed oil heat exchange, save energy.

5. the tail gas recovery uses the water bath type tail gas recovery device, the tail gas recovery two times utilization, reduces the solvent consumption.

tag : Solvent extraction,Oil press,method,solvent extracted oil

soybean solvent extraction,sunflower seed solvent extraction ,,High-quality solvent extraction device, which is mainly composed of extraction desolventizer, evaporator, DTDC decontamination machine, stripper and condenser, low solvent consumption, high degree of automation, processing capacity 20-1000TPD