Oil Refining Plant(Soybean oil,sunflower oil,peanut oil)

- Henan Victor Machinery Equipment Co.,Ltd

- Made In China

- Oil Refining Machine-32

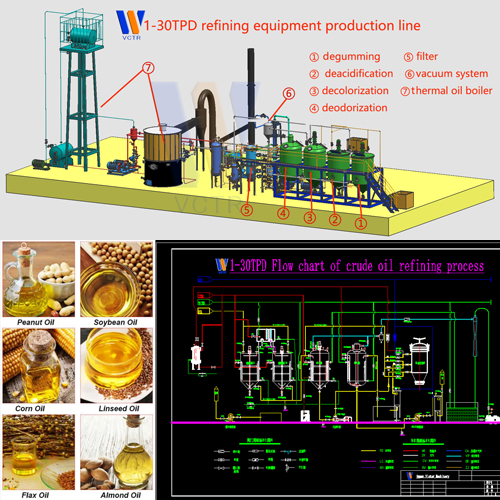

Henan Victor Machinery Equipment Co.,Ltd can design and manufacture 50-500T/D sunflower oil, soybean oil, sunflower oil, peanut oil, cottonseed oil, palm oil, rice bran oil, olive oil refineries

Oil Refining Plant(Soybean oil,sunflower oil,peanut oil) details

Oil Refining Plant Introduction

Basing on the traditional oil refining technology, Henan Victor Machinery Equipment Co. , Ltd has developed the latest combined packing layer plate deodorization soft tower and the physical and chemical mixed refining technology for crude oil of any quality. Moreover, a series of advanced technology and equipment are used, such as super wet deguming, bleaching earth automatic metering, negative pressure decoloring, high vacuum steam jet deodorization, deacidification, winterization dewaxing etc. With advanced technology, superior equipment, full-automatic control and excellent economic and technical parameters, our equipment can meet customers' different refining requirements at home and abroad.

Basing on the traditional oil refining technology, Henan Victor Machinery Equipment Co. , Ltd has developed the latest combined packing layer plate deodorization soft tower and the physical and chemical mixed refining technology for crude oil of any quality. Moreover, a series of advanced technology and equipment are used, such as super wet deguming, bleaching earth automatic metering, negative pressure decoloring, high vacuum steam jet deodorization, deacidification, winterization dewaxing etc. With advanced technology, superior equipment, full-automatic control and excellent economic and technical parameters, our equipment can meet customers' different refining requirements at home and abroad.

Oil Refining Workshop Exterior

1. Continuous Oil Refining Process Introduction

2. Main Processes Introduction

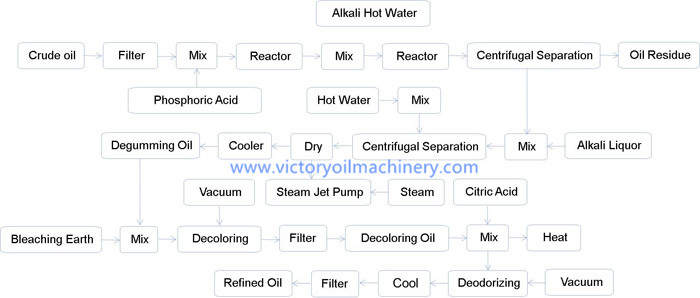

2.1 Hydration Deguming & Alkali Refining Deacidification Process

Neutralization: the crude oil is output by the oil feed pump from the oil tank, and next enters the crude oil heat exchanger to recover part of heat after metering and then is heated to the required temperature by the heater. After that, the oil is mixed with the metered phosphoric acid or citric acid from phosphate tank in the gas mixture (M401), and then enters the conditioning tank (R401) to make the non-hydratable phospholipids in oil change into the hydratable phospholipids. Add the alkali for neutralization, and the alkali quantity and alkali solution concentration depend on the quality of the crude oil. Through the heater, the neutralized oil is heated to the temperature (90℃) suitable for centrifugal separation to remove the phospholipids, FFA and other impurities in the crude oil. Then the oil goes to the washing process.

Washing: there is still about 500ppm soap in the neutralized oil from the separator. To remove the remaining soap, add into the oil about 5~8% hot water, with water temperature 3~5 ℃ higher than the oil generally. To achieve more stable washing effect, add phosphoric acid or citric acid when washing. The re-mixed oil and water in the mixer is heated to 90-95℃ by the heater, and then enters the wash separator to separate the remaining soap and most water. The water with soap and oil enters into oil separator to separate out oil in the water. Further catch the oil outside, and the waste water is discharged to the sewage treatment station.

Vacuum Drying Stage: there is still moisture in the oil from the wash separator, and the moisture will affect the stability of the oil. So the oil at 90℃ should be sent to vacuum drier to remove the moisture, and then the dehydrated oil goes to the decoloring process. Finally, pump out the dry oil by canned pump.

Washing: there is still about 500ppm soap in the neutralized oil from the separator. To remove the remaining soap, add into the oil about 5~8% hot water, with water temperature 3~5 ℃ higher than the oil generally. To achieve more stable washing effect, add phosphoric acid or citric acid when washing. The re-mixed oil and water in the mixer is heated to 90-95℃ by the heater, and then enters the wash separator to separate the remaining soap and most water. The water with soap and oil enters into oil separator to separate out oil in the water. Further catch the oil outside, and the waste water is discharged to the sewage treatment station.

Vacuum Drying Stage: there is still moisture in the oil from the wash separator, and the moisture will affect the stability of the oil. So the oil at 90℃ should be sent to vacuum drier to remove the moisture, and then the dehydrated oil goes to the decoloring process. Finally, pump out the dry oil by canned pump.

2.2. Continuous Refining Decoloring Process

The main function of decoloring process is to remove oil pigment, residual soap grain and metal ions. Under negative pressure, the mechanical mixing method combined with steam mixing will improve the decoloring effect.

The degummed oil firstly enters in to the heater to be heated to the appropriate temperature (110℃), and then goes to the bleaching earth mixing tank. The bleaching earth is delivered from the low bleaching box to the temporary tank by wind. The bleaching earth is added by automatic metering and is interlockingly controlled with the oil.

The degummed oil firstly enters in to the heater to be heated to the appropriate temperature (110℃), and then goes to the bleaching earth mixing tank. The bleaching earth is delivered from the low bleaching box to the temporary tank by wind. The bleaching earth is added by automatic metering and is interlockingly controlled with the oil.

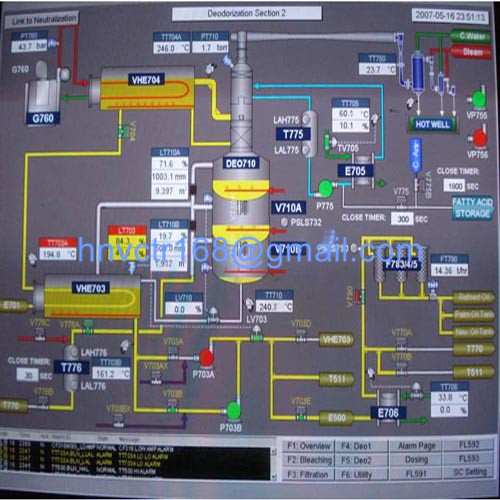

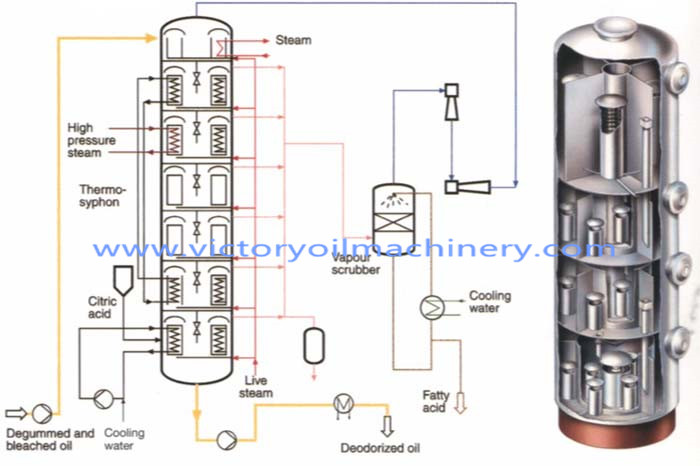

2.3. Continuous Refining Deodorizing Process

The qualified decolored oil enters into the spiral plate heat exchanger to recover most of the heat, and next goes to high pressure steam heat exchanger to be heated to the process temperature (240-260℃) and then enters the deodorization tower. The upper layer of combined deodorization tower is the packing structure which is mainly used to remove the odor producing components such as free fatty acid (FFA); the bottom layer is the plate tower which is mainly for achieving the hot decoloring effect and reducing the peroxide value of the oil to zero. Oil from the deodorization tower enters into the heat exchanger to recover most of the heat and makes further heat exchange with crude oil, and then is cooled to 80-85℃ through the cooler. Add the required antioxidant and flavor agent, and then cool the oil below 50℃ and store it. Such volatiles as FFA from the deodorizing system are separated by the packing catcher, and the separated liquid is FFA at low temperature (60-75℃). When the liquid level in the temporary tank is too high, the oil will be sent to the FFA storage tank.

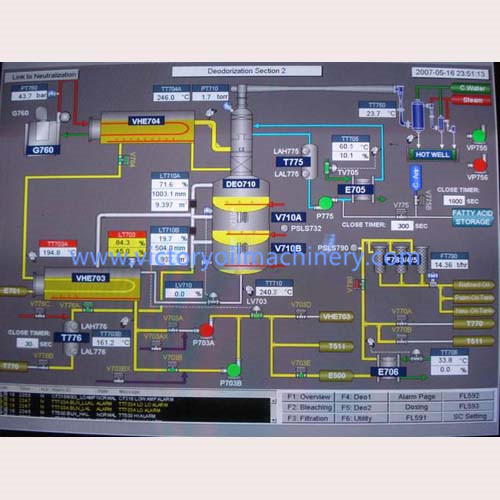

2.4. Automatic Control System

Our company has applied the automatic control system with advancedness, security, reliability into the pretreatment, extraction, refining and fractionation in large oil plants. For its application in automatic control system, it can control the production in the entire workshop and monitor the operational status of each device by controlling the computer terminals in the room. One person only can operate the entire workshop, with efficient production management. It has reduced the production cost greatly and improved the management efficiency.

tag : Soybean oil refining,sunflower oi refining,peanut oil refinin

Oil Refining Plant(Soybean oil,sunflower oil,peanut oil),Henan Victor Machinery Equipment Co.,Ltd can design and manufacture 50-500T/D sunflower oil, soybean oil, sunflower oil, peanut oil, cottonseed oil, palm oil, rice bran oil, olive oil refineries