High-quality corn oil production equipment made in China

- Henan Victor Machinery Equipment Co.,Ltd

- Made In China

- Oil Production line-69

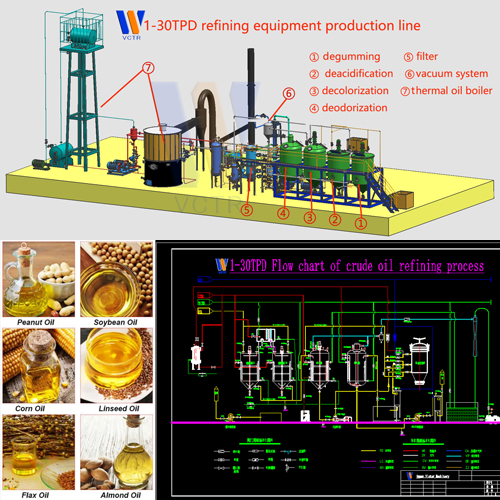

Our company uses the most advanced corn oil processing technology and technology. We have our own unique patent, high degree of automation, and the best corn oil index. Can handle 10-500TPD tonnage

High-quality corn oil production equipment made in China details

High-quality corn oil production equipment made in China

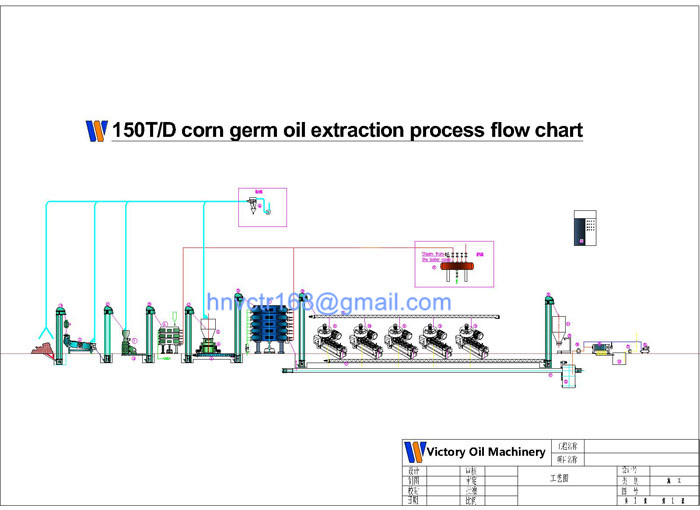

1.Description of 150TPD corn germ pretreatment and pressing oil production technology

Dust removal→fan

↑

Raw materials → warehousing raw material warehouse → cleaning → crushing embryos → steaming and frying → oil extraction → cakes → go to cake storage ↓

Gross oil tank→filter→refining workshop

2 Process description

2.1 Clean up

Raw materials go through a vibrating cleaning screen to remove large and small impurities in the raw materials;

Then enter the specific gravity stone remover to remove side-by-side mud and side-by-side stones in the material;

The dust in the material is removed by the fan and dust removal air net;

The iron impurities in the material will affect the life of the mechanical equipment, and there is a magnetic separator in the process to remove the iron impurities in the material.

2.2 Broken embryo

The purpose of crushing the embryo is to destroy the cell structure of the oil, which is conducive to the transfer of temperature and moisture during steaming and frying, and is more conducive to the oil production in the subsequent sections. After the oil is pressed, the thickness of the green sheet is uniform, no oil, no agglomeration, less powder, and the thickness meets the requirements.

2.3 Steaming

Steaming and frying is to adjust the moisture and temperature of the oil to meet the requirements of high temperature and low moisture in the raw material.

The steamed rapeseeds are sent to the pressing process through the conveying equipment.

2.4 Press

After the pretreatment of the material is completed, it can enter the oil press for squeezing. The one-time large screw press used in this process is 200A-3, which has the advantages of high automation and low residual oil.

The configuration number is 5, and the benefits of a few more oil presses: the output adjustment is flexible, and the rest of the equipment can continue to work when one is maintained, and the impact on the production capacity is also small.

2.5 filter

The squeezed crude oil is filtered to remove the particulate impurities in the grease, and the filtered oil is clear and bright with good color.

3. Process technology characteristics

The design of the dust removal system is reasonable, and the discharged gas meets the national environmental protection requirements;

High degree of automation, 1-2 workers can complete the operation of the entire production equipment.

Multiple one-time squeezing screw oil presses have low residual oil and flexible output, which reduces the impact on production capacity during equipment maintenance.

4. Process index consumption

Power consumption: less than 35KWH/ton material

Steam consumption: less than 300Kg/ton material

Residual oil in cake: 6-7% or less

Steaming and frying pan temperature: 105-120

Water content in cake: less than 6%

Impurities in oil: less than 0.1%

tag : corn oil machine,corn oil production equipment

High-quality corn oil production equipment made in China,Our company uses the most advanced corn oil processing technology and technology. We have our own unique patent, high degree of automation, and the best corn oil index. Can handle 10-500TPD tonnage