High quality soybean oil production line with oil refinery equipment

- Henan Victor Machinery Equipment Co.,Ltd

- Made In China

- Oil Production line-66

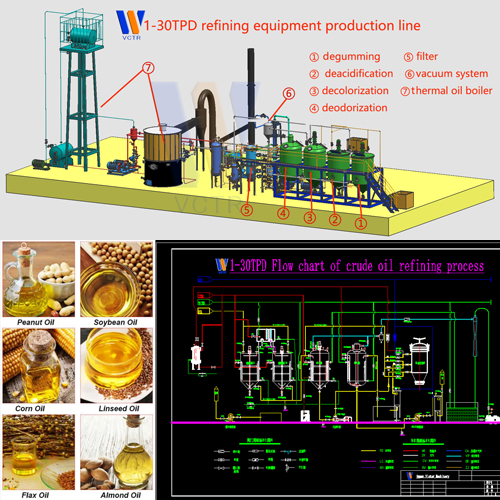

Our company adopts the most advanced soybean oil processing technology and technology. There are more than 20 successful cases at home and abroad, with high degree of automation and low failure rate. The handling tonnage is 10-2000TPD

High quality soybean oil production line with oil refinery equipment details

Technological process introduction

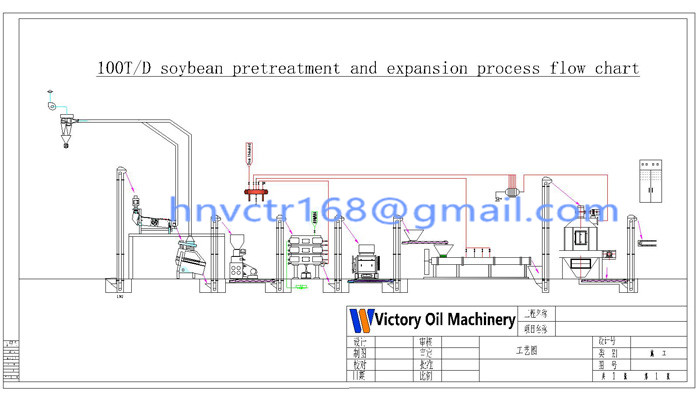

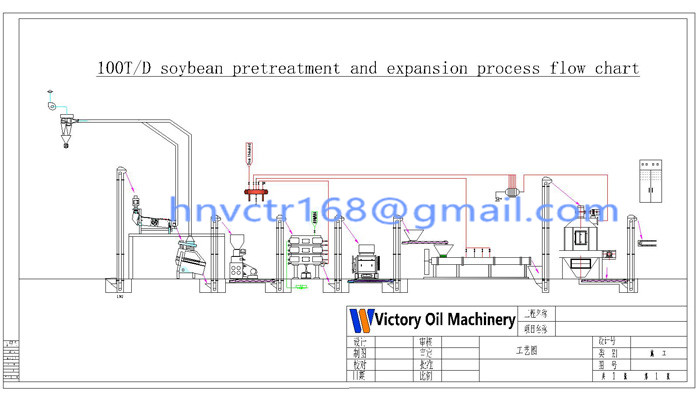

1.Soybean pretreatment flow chart:

Soybean→Magnetic separation→Cleaning→Crusher→Flaker→Extrusion Puffing →Counter-current drying→To leaching plant

2.Main process description

2.1 Cleaning process:

In order to obtain high effective cleaning, ensure good work condition and production stability, high efficient vibration screen was used in the process to separate big and small impurity. Suction type gravity stoner removing machine was applied to remove the shoulder stone and earth, and magnetic separation equipment without power and exhaust system were used to remove iron. Dust removing wind net is installed.

2.2 Crush:In order to ensure good softening and flaking effect, soy is generally broken up uniformly to 5~6 flakes and water distribute uniformly during softening, and flakes is thin and burliness.

2.3 Conditioning process: conditioning’s purpose is heating and cooking cottonseed, which is easy for extrusion, improving crude oil quality, and separating oil.

2.4 Flaking:Flaking means a certainty granularity of soy lamella was prepared

for flaked of about 0.3 mm, the oil of raw material can be extracted in the shortest time and maximum, and residual oil was less than 1%.

2.5 Extrusion process:

Adopting the bulking machine can both improve the yield of rice bran oil and reduce the consumption. The extrusion puffing, on the one hand, can make solution lipase in the rice bran passivated under high temperature and high pressure condition,then prevent the rice bran oil rancidity; On the other hand, the extrusion puffing can make rice bran be porous mateial grain, and increases the materials bulk density, then improve the permeability and leaching rate which solvent reacts to the material.

2.6 Drying process:

The puffed rice bran contains about 12% water, and the best moisture for leaching process is 7-9%, therefore, there must be effective drying means to achieve the best leaching moisture.Adopting counter-current dryer can make water and temperature meet with follow-up process requirements, and improve the oil yield, as well as oil quality.

The puffed rice bran contains about 12% water, and the best moisture for leaching process is 7-9%, therefore, there must be effective drying means to achieve the best leaching moisture.Adopting counter-current dryer can make water and temperature meet with follow-up process requirements, and improve the oil yield, as well as oil quality.

3. Pretreatment process feature

3.1Different combinations of process can process various oil plants in one workshop.

3.2Use special intensified pretreatment technology for aroma peanut oil to make it more aroma.

3.3 Adopt advanced and reliable shelling technology to meet higher requirements for protein content in meal.

3.4 Extrusion treatment is used for raw materials with hard extraction, large-sized powder, and large capacity, which can reduce residual oil and solvent consumption, and increase the capacity by 50-80%.

3.5 The new technology of shelling and low-temperature treatment can ensure high protein and least denaturation.

4. About us

Soybean→Magnetic separation→Cleaning→Crusher→Flaker→Extrusion Puffing →Counter-current drying→To leaching plant

2.Main process description

2.1 Cleaning process:

In order to obtain high effective cleaning, ensure good work condition and production stability, high efficient vibration screen was used in the process to separate big and small impurity. Suction type gravity stoner removing machine was applied to remove the shoulder stone and earth, and magnetic separation equipment without power and exhaust system were used to remove iron. Dust removing wind net is installed.

2.2 Crush:In order to ensure good softening and flaking effect, soy is generally broken up uniformly to 5~6 flakes and water distribute uniformly during softening, and flakes is thin and burliness.

2.3 Conditioning process: conditioning’s purpose is heating and cooking cottonseed, which is easy for extrusion, improving crude oil quality, and separating oil.

2.4 Flaking:Flaking means a certainty granularity of soy lamella was prepared

for flaked of about 0.3 mm, the oil of raw material can be extracted in the shortest time and maximum, and residual oil was less than 1%.

2.5 Extrusion process:

Adopting the bulking machine can both improve the yield of rice bran oil and reduce the consumption. The extrusion puffing, on the one hand, can make solution lipase in the rice bran passivated under high temperature and high pressure condition,then prevent the rice bran oil rancidity; On the other hand, the extrusion puffing can make rice bran be porous mateial grain, and increases the materials bulk density, then improve the permeability and leaching rate which solvent reacts to the material.

2.6 Drying process:

The puffed rice bran contains about 12% water, and the best moisture for leaching process is 7-9%, therefore, there must be effective drying means to achieve the best leaching moisture.Adopting counter-current dryer can make water and temperature meet with follow-up process requirements, and improve the oil yield, as well as oil quality.

The puffed rice bran contains about 12% water, and the best moisture for leaching process is 7-9%, therefore, there must be effective drying means to achieve the best leaching moisture.Adopting counter-current dryer can make water and temperature meet with follow-up process requirements, and improve the oil yield, as well as oil quality.

3. Pretreatment process feature

3.1Different combinations of process can process various oil plants in one workshop.

3.2Use special intensified pretreatment technology for aroma peanut oil to make it more aroma.

3.3 Adopt advanced and reliable shelling technology to meet higher requirements for protein content in meal.

3.4 Extrusion treatment is used for raw materials with hard extraction, large-sized powder, and large capacity, which can reduce residual oil and solvent consumption, and increase the capacity by 50-80%.

3.5 The new technology of shelling and low-temperature treatment can ensure high protein and least denaturation.

4. About us

Henan Victor Machinery Equipment Co.,Ltd

Our Company located in grain and oil hometown of China(cover more an 2/3market in China),we are a professional oil engineering company which offer variety of service such as design,manufacture,installation,debugging,after-sales service etc.

Our company owns a design team which constitutes with senior engineers and experts.We are offering the efficient and quick service to inland and abroad customers by using us advanced technology and equipment.Our company has grown into Chinese grain and oil machinery production and export base,our production and the comprehensive economy indicators lies in the forefront of the same industry line,The products have been sold all over the country and exported to many countries and regions such as Nigerian,Tajikistan,Kazakhstan,South Africa,Ukraine, many other countries and regions.

Our Company located in grain and oil hometown of China(cover more an 2/3market in China),we are a professional oil engineering company which offer variety of service such as design,manufacture,installation,debugging,after-sales service etc.

Our company owns a design team which constitutes with senior engineers and experts.We are offering the efficient and quick service to inland and abroad customers by using us advanced technology and equipment.Our company has grown into Chinese grain and oil machinery production and export base,our production and the comprehensive economy indicators lies in the forefront of the same industry line,The products have been sold all over the country and exported to many countries and regions such as Nigerian,Tajikistan,Kazakhstan,South Africa,Ukraine, many other countries and regions.

tag : Soybean Oil Production Line,Soybean Oil machine

High quality soybean oil production line with oil refinery equipment,Our company adopts the most advanced soybean oil processing technology and technology. There are more than 20 successful cases at home and abroad, with high degree of automation and low failure rate. The handling tonnage is 10-2000TPD