Significance of palm oil refining and fractionation

1. The production significance of palm oil refining and fractionation

In the global market, there is widespread market demand for low-grade palm oil to replace soybean oil and peanut oil. However, there is a phenomenon that the quality of fractionated low-degree oil is unstable and the oil is dark in color. Therefore, the production and fractionation of stable low-degree palm oil, after decolorization and deodorization, can be more easily accepted by various users, making the product more competitive in the market.

In the global market, there is widespread market demand for low-grade palm oil to replace soybean oil and peanut oil. However, there is a phenomenon that the quality of fractionated low-degree oil is unstable and the oil is dark in color. Therefore, the production and fractionation of stable low-degree palm oil, after decolorization and deodorization, can be more easily accepted by various users, making the product more competitive in the market.

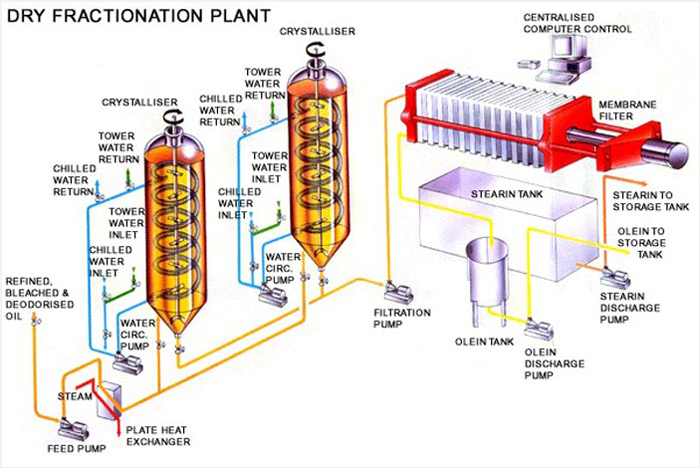

Dry fractionation plant

2. The technical core of palm oil refining and fractionation

Principle: How to minimize investment on the premise of ensuring the quality of finished products.

1) The main technological points of the separation process

a.The crystallization and crystallization process is very critical. The mature palm oil refining and fractionation process can be adopted to make sure that the equipment has reasonable equipment assembly, cooling area and other process parameters.

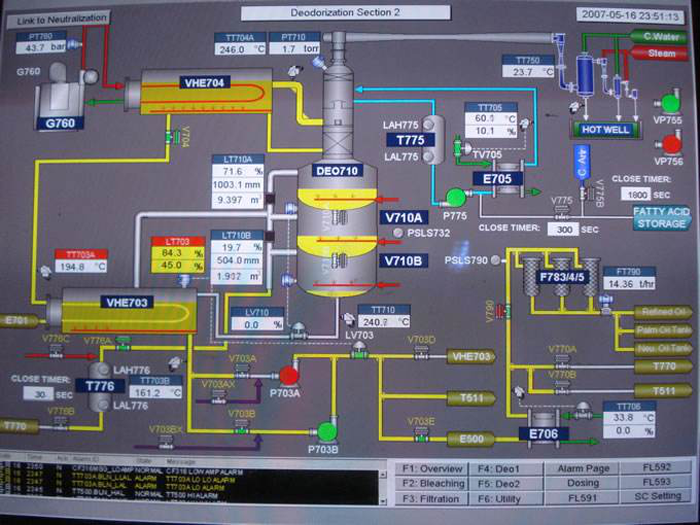

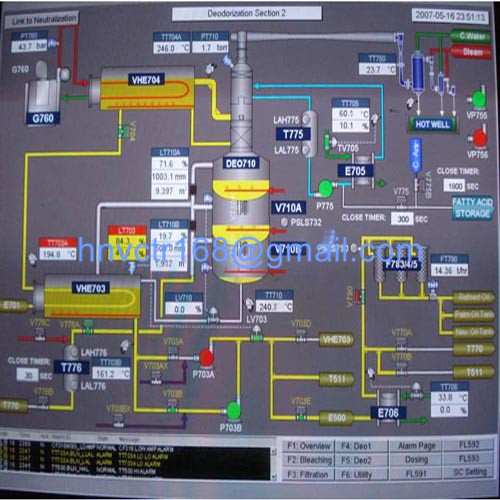

b. Automatic control and electromechanical supporting equipment are the hardware conditions to achieve stable quality.

palm oil refining and fractionation

c. Selection of filter press

On the basis of several sets of palm oil fractionation, construction and commissioning, Victor Machinery Co., Ltd. has developed its own unique set of special filter presses with a high degree of automation, which can guarantee the same process conditions on the basis of filter presses. The investment cost can be reduced by 5 to 6 times.

d. A full set of turnkey projects for complete process matching, installation and commissioning.

2) For equipment selection, such as crystallizing tanks and finished tanks, use carbon steel structure. Without affecting product quality, use carbon steel with anti-rust coating as much as possible to meet production requirements. The appearance adopts stainless steel mirror plate for heat preservation. In this way, the overall appearance is more spectacular, and the investment cost is reasonably controlled.

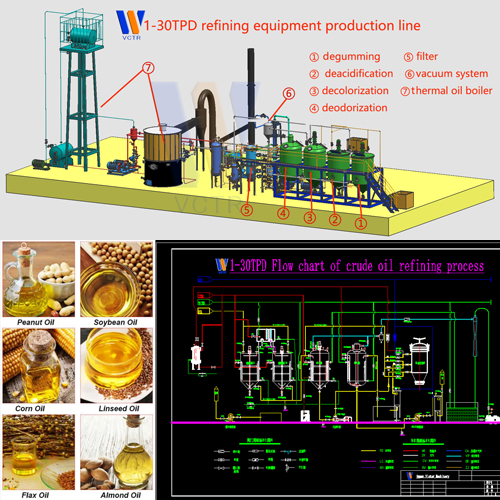

3) Using a special physical refining process, dry degumming, physical decolorization and deacidification, so that the quality of the finished palm oil is better and the energy consumption is lower.

On the basis of several sets of palm oil fractionation, construction and commissioning, Victor Machinery Co., Ltd. has developed its own unique set of special filter presses with a high degree of automation, which can guarantee the same process conditions on the basis of filter presses. The investment cost can be reduced by 5 to 6 times.

d. A full set of turnkey projects for complete process matching, installation and commissioning.

2) For equipment selection, such as crystallizing tanks and finished tanks, use carbon steel structure. Without affecting product quality, use carbon steel with anti-rust coating as much as possible to meet production requirements. The appearance adopts stainless steel mirror plate for heat preservation. In this way, the overall appearance is more spectacular, and the investment cost is reasonably controlled.

3) Using a special physical refining process, dry degumming, physical decolorization and deacidification, so that the quality of the finished palm oil is better and the energy consumption is lower.

palm oil refining and fractionation

3. Quality index requirements

The product quality is required to reach:

1) The iodine value is above 63, 63-65; the freezing point is 10℃, and the yield is above 50%.

2) The iodine value is 60-62, the freezing point is 15°C, and the yield is more than 60%.

30 iodine value 56, freezing point 24 ℃, the yield is more than 75%.

Process consumption requirements meet:

1) Low energy consumption.

2) The product quality is stable.

3) The variety of products can be set automatically by computer. Different production parameters, adjust the production process at any time, change the production with software parameters, and extract different fractions of oil at 33°C, 24°C, 15°C, 10°C, etc., without additional investment in hardware equipment.

Choosing Victor machinery is to choose to rest assured, welcome domestic and foreign investment customers who need palm oil refining and fractionation equipment to visit our company for inspection and negotiation.

The product quality is required to reach:

1) The iodine value is above 63, 63-65; the freezing point is 10℃, and the yield is above 50%.

2) The iodine value is 60-62, the freezing point is 15°C, and the yield is more than 60%.

30 iodine value 56, freezing point 24 ℃, the yield is more than 75%.

Process consumption requirements meet:

1) Low energy consumption.

2) The product quality is stable.

3) The variety of products can be set automatically by computer. Different production parameters, adjust the production process at any time, change the production with software parameters, and extract different fractions of oil at 33°C, 24°C, 15°C, 10°C, etc., without additional investment in hardware equipment.

Choosing Victor machinery is to choose to rest assured, welcome domestic and foreign investment customers who need palm oil refining and fractionation equipment to visit our company for inspection and negotiation.