Comparison of solvent extracted oil and pressed oil

As in my country and internationally, there are generally two methods for preparing edible vegetable oil: pressing method and solvent extraction method. The pressing method is a method of squeezing oil from the oil by mechanical pressing. It originated from traditional oil production methods in workshops. Although today's pressing method is already a large-scale and industrialized operation, the basic principles have not changed. The solvent extraction method is a method that uses the extraction principle of food engineering and uses internationally recognized and universal food-grade solvents to extract oil from the oil. This kind of extraction is essentially a physical dissolution process, and no chemical reaction between oil and solvent occurs during the extraction process.

Judging from the development history of the world's edible oil preparation process, the solvent extraction oil preparation process is currently the most advanced production process recognized internationally. At the beginning of the twentieth century, the solvent extraction method was first applied and developed in developed countries. In developed countries such as Europe and the United States, more than 90% of vegetable oils are now produced by solvent extraction. For more than half a century, especially since the reform and opening up, my country's oil science and technology workers have introduced, digested, absorbed and re-innovated foreign advanced technology, so that the solvent extraction method of oil production technology has been widely used in my country's oil production and achieved With rapid development, solvent extraction oil production has accounted for more than 80% of the entire oil production capacity, and its equipment and technical level have reached the current international advanced level.

The solvent extraction process uses a hydrocarbon solvent with n-hexane as the main component. It was once called "No. 6 solvent oil", but is now revised as "vegetable oil extraction solvent". It is a special solvent produced by the state for oil processing. High ordinary gasoline has an essential difference. This extraction solvent must be food-grade, that is, after heavy metal removal treatment, the residual amount of harmful substances such as lead and arsenic is less than 10μg/kg (one billionth), so , The finished vegetable oil, which is leached with qualified solvents and removed to the greatest extent according to national standards during the refining process, is absolutely safe.

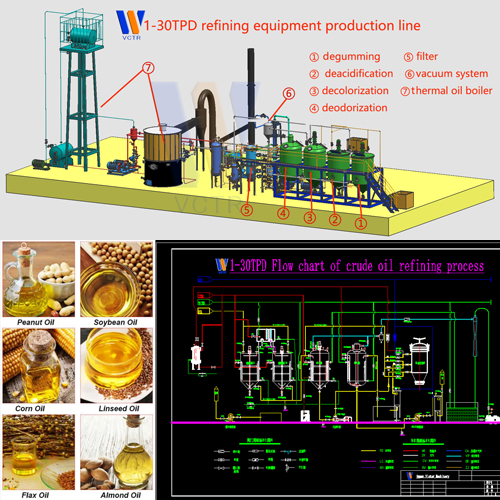

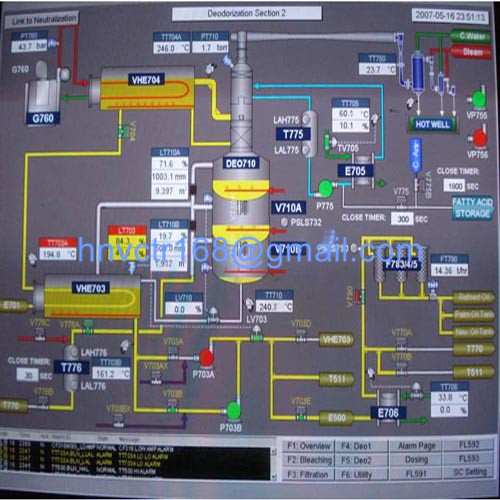

The processing process from crude oil to refined oil generally involves degumming, deacidification, decolorization, and deodorization. In other words, squeezing and solvent extraction only solve the problem of crude oil production, and to turn crude oil into refined oil, it must go through a refining process.

It can be seen that the safety of edible oil does not depend on whether the pressing or solvent extraction process is used, but is mainly determined by the subsequent refining process. Since the boiling point of n-hexane is less than 70°C, it is easy to remove cleanly during the refining process. In fact, my country's national standard stipulates that the solvent residues in high-grade refined oil (primary oil and secondary oil) cannot be detected, that is to say, the use of advanced instruments specified in the national standard cannot detect solvent residues in high-grade refined oil.

There is no difference between the solvent extraction process and the pressing process. Which process to choose for oil preparation, the first consideration is the variety of vegetable oil and its processing characteristics. The two oil preparation processes only have the applicability of raw materials. The current international general practice is: vegetable oils with higher oil content (such as peanuts and rapeseeds) are usually pressed and then leached to make oil; vegetable oils with lower oil content (such as soybeans, etc.) are usually used Direct solvent extraction process to make oil. In order to make full use of oil resources and improve economic efficiency, the oil cakes after pressing generally have to continue to be leached to make oil. Compared with the pressing process, the solvent extraction process has the advantages of less residual oil in the meal, high oil yield, low processing cost, good production conditions, and full utilization of oil resources. In short, whether it is solvent extraction oil or pressing oil, as long as it meets my country's edible oil quality standards and sanitary standards, it is high-quality and safe edible oil, and consumers can eat with confidence.

Some people in the society describe the "vegetable oil extraction solvent" used in the solvent extraction process as "No. 6 light gasoline" and analogy with ordinary gasoline, which is really alarmist.

Judging from the development history of the world's edible oil preparation process, the solvent extraction oil preparation process is currently the most advanced production process recognized internationally. At the beginning of the twentieth century, the solvent extraction method was first applied and developed in developed countries. In developed countries such as Europe and the United States, more than 90% of vegetable oils are now produced by solvent extraction. For more than half a century, especially since the reform and opening up, my country's oil science and technology workers have introduced, digested, absorbed and re-innovated foreign advanced technology, so that the solvent extraction method of oil production technology has been widely used in my country's oil production and achieved With rapid development, solvent extraction oil production has accounted for more than 80% of the entire oil production capacity, and its equipment and technical level have reached the current international advanced level.

The solvent extraction process uses a hydrocarbon solvent with n-hexane as the main component. It was once called "No. 6 solvent oil", but is now revised as "vegetable oil extraction solvent". It is a special solvent produced by the state for oil processing. High ordinary gasoline has an essential difference. This extraction solvent must be food-grade, that is, after heavy metal removal treatment, the residual amount of harmful substances such as lead and arsenic is less than 10μg/kg (one billionth), so , The finished vegetable oil, which is leached with qualified solvents and removed to the greatest extent according to national standards during the refining process, is absolutely safe.

The processing process from crude oil to refined oil generally involves degumming, deacidification, decolorization, and deodorization. In other words, squeezing and solvent extraction only solve the problem of crude oil production, and to turn crude oil into refined oil, it must go through a refining process.

It can be seen that the safety of edible oil does not depend on whether the pressing or solvent extraction process is used, but is mainly determined by the subsequent refining process. Since the boiling point of n-hexane is less than 70°C, it is easy to remove cleanly during the refining process. In fact, my country's national standard stipulates that the solvent residues in high-grade refined oil (primary oil and secondary oil) cannot be detected, that is to say, the use of advanced instruments specified in the national standard cannot detect solvent residues in high-grade refined oil.

There is no difference between the solvent extraction process and the pressing process. Which process to choose for oil preparation, the first consideration is the variety of vegetable oil and its processing characteristics. The two oil preparation processes only have the applicability of raw materials. The current international general practice is: vegetable oils with higher oil content (such as peanuts and rapeseeds) are usually pressed and then leached to make oil; vegetable oils with lower oil content (such as soybeans, etc.) are usually used Direct solvent extraction process to make oil. In order to make full use of oil resources and improve economic efficiency, the oil cakes after pressing generally have to continue to be leached to make oil. Compared with the pressing process, the solvent extraction process has the advantages of less residual oil in the meal, high oil yield, low processing cost, good production conditions, and full utilization of oil resources. In short, whether it is solvent extraction oil or pressing oil, as long as it meets my country's edible oil quality standards and sanitary standards, it is high-quality and safe edible oil, and consumers can eat with confidence.

Some people in the society describe the "vegetable oil extraction solvent" used in the solvent extraction process as "No. 6 light gasoline" and analogy with ordinary gasoline, which is really alarmist.